Industrial Equipment & Facilities Monitoring

Distributed Acoustic Sensing (DAS) is an effective method for industrial equipment and facilities monitoring for several reasons:

- Continuous Monitoring: DAS allows for continuous monitoring of large areas, providing real-time data on the condition of equipment and infrastructure. This is particularly useful in industrial settings where downtime can be costly and potentially dangerous.

- Non-Invasive: DAS is a non-invasive monitoring method, which means it does not require physical contact with the equipment or infrastructure being monitored. This makes it a cost-effective and low-risk monitoring option, especially for equipment and facilities that are difficult to access or located in hazardous environments.

- High Sensitivity: DAS can detect very small changes in vibrations and acoustic waves, which can provide early warning of equipment or infrastructure failure. This can allow for preventative maintenance to be carried out before a failure occurs, reducing downtime and repair costs.

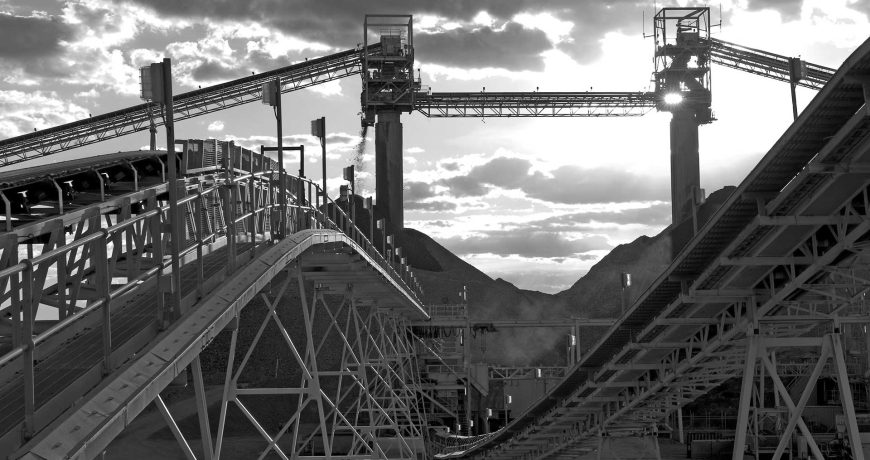

- Versatility: DAS can be used to monitor a wide range of industrial equipment and facilities including conveyors, pipelines, bridges, railways, and power transmission lines.

Overall, distributed acoustic sensing is an effective monitoring method for industrial equipment and facilities because it provides continuous, non-invasive, sensitive, and versatile monitoring that helps the operator to prevent accidents, reduce downtime, and improve safety and efficiency.